Establishing an organic fertilizer production plant requires careful consideration of setup costs and efficiency. Process optimization serves as a critical strategy for reducing organic fertilizer plant setup costs while maintaining product quality. Businesses seeking to enter the organic fertilizer granulation industry or expand capacity must analyze every production stage. Through refined process design and strategic equipment selection, operators can realize substantial savings and enhanced profitability.

What Types of Raw Materials Are Suitable for Organic Fertilizer Granulation Processes?

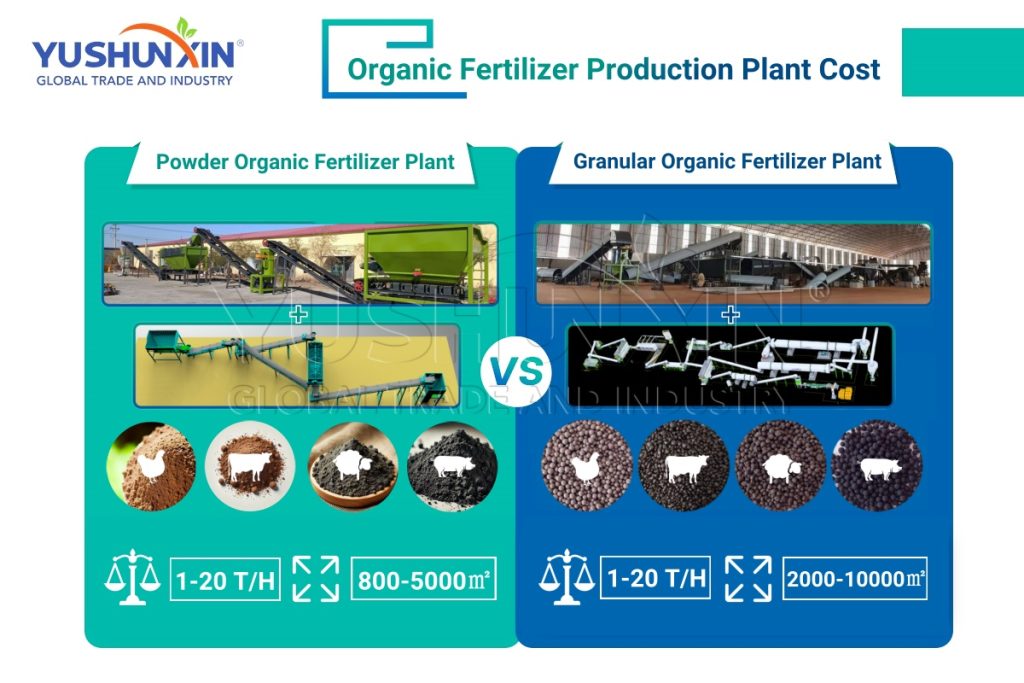

Selecting suitable raw materials for organic fertilizer production lines directly impacts granulation efficiency and overall plant costs. Animal manure, such as chicken, cow, or pig manure, remains one of the primary materials for organic fertilizer granule making. Other viable options include livestock waste, crop straw, kitchen waste, municipal sludge, and even agricultural by-products like distillers’ grains or mushroom residue. Each raw material presents different moisture levels, nutrient profiles, and physical characteristics, which influence the requirements for crushing, composting, and granulating machinery. Combining compatible materials allows the production procedure to achieve better fermentation, granulation, and drying results, which ultimately reduces organic fertilizer production plant costs by minimizing energy use and avoiding unnecessary material wastage.

How Do Efficient Machines and Production Lines Influence Organic Fertilizer Plant Setup Costs?

Modern organic fertilizer granulation equipment plays a significant role in optimizing plant setup costs. Operators should evaluate the most appropriate granulator for their raw material characteristics and desired pellet shapes, such as disc granulators, flat die pelletizers, double roller extrusion granulators, or drum granulating machines. Advanced machines enhance granule uniformity, improve pelletizing yield, and lower maintenance requirements. In addition to granulators, supporting machinery such as crushing machines, rotary drying equipment, and automatic screening systems streamline the process and minimize labor input. Process automation and modular design can further reduce fertilizer manufacturing plant costs by shortening installation time and enabling flexible scaling. Efficient equipment requires less floor space and energy, contributing to overall fertilizer factory cost reductions. Selecting the right production line configuration—tailored to your capacity, raw materials, and end-product specifications—will ensure sustainable cost control and operational stability.

How Can Process Optimization Strategies Reduce Organic Fertilizer Production Plant Costs?

Process optimization focuses on integrating every stage of the organic fertilizer pellet making process for maximum economic benefit. By analyzing raw material properties, refining composting periods, and using efficient crushing, mixing, and granulating systems, operators can minimize energy and resource consumption. Strategic batching and feeding can reduce material loss and improve granulation efficiency, while moisture control throughout drying and cooling ensures high-quality organic fertilizer pellets or granules. Implementing advanced pellet screening and packing machines can eliminate reprocessing needs, cutting labor costs and waste. Continuous process monitoring supports fast adjustments and maintenance, which prevents downtime and costly repairs. In summary, an optimized organic fertilizer pellet production line balances quality, throughput, and cost, enabling businesses to achieve lower organic fertilizer plant setup costs and rapid return on investment.

Conclusion

In summary, successful organic fertilizer production relies on selecting suitable raw materials, choosing efficient granulation equipment, and applying comprehensive process optimization. Each decision in raw material blending, process design, and machine selection directly impacts organic fertilizer production plant costs. Businesses that invest in advanced granulating technology and customized production lines can gain a competitive advantage by reducing their fertilizer manufacturing plant costs. For those seeking reliable solutions and industry-leading expertise, partnering with a professional fertilizer equipment manufacturer such as Yushunxin offers access to innovative production line designs, tailored machinery, and expert guidance that ensures both high-quality organic fertilizer granule production and significant setup cost savings. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/