Mineral-based fertilizers play a critical role in modern industrial and environmental applications. The transformation of mined ore materials into uniform fertilizer particles requires a precise and efficient production method. Pan granulation, also known as disc granulation, provides such a pathway by enabling the controlled conversion of fine mineral powders into dense, spherical granules. This process connects the mining, chemical, and material-handling industries through a unified production system. When ore materials undergo granulating procedures, they acquire higher bulk density, improved flowability, and enhanced reactivity, all of which are essential for further industrial use or market distribution.

What Types of Ore Materials Are Suitable for Fertilizer Granulation?

Different mineral resources support the manufacturing of various mineral fertilizer products. Phosphate rock, for example, serves as a primary material in rock phosphate fertilizer production where granulation improves solubility and nutrient availability. Limestone and dolomite provide calcium-based minerals for limestone fertilizer production solutions and for blending in NPK fertilizer lines. Iron ore dust or mine tailings can also become part of mineral organic fertilizer production lines or mine waste management projects, where granulation stabilizes the fine particles and reduces environmental risks.

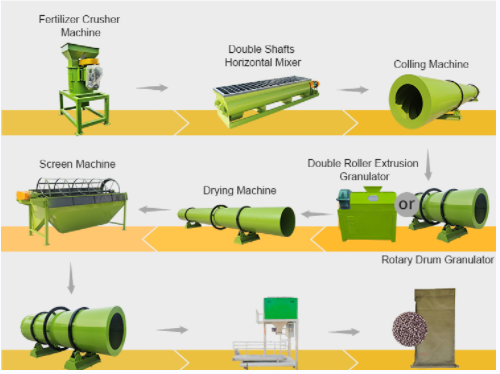

Each raw material requires specific preparation steps. Crushing machines, such as a jaw rock crusher or ore fertilizer crusher machine, reduce the mined ore into smaller particles. Grinding equipment like a Raymond mill can refine the particle size before granulation. These pre-processing stages ensure consistent feeding for the pan granulator and uniform granule formation. Industries that handle mining residues or mineral additives can also benefit since granulation facilitates transportation, dust reduction, and controlled nutrient release.

How Does Pan or Disc Granulation Function in Ore Fertilizer Manufacturing?

The pan granulation process relies on a rotating disc or pan granulator that continuously mixes and agglomerates mineral powders with controlled moisture and binder addition. The rotation of the disc creates a rolling bed of particles, allowing fine ore dust to coalesce into uniform spherical granules. In mineral fertilizer manufacturing, this principle ensures that each particle maintains mechanical strength and homogeneous mineral composition.

A disc granulation machine allows flexible control over granule size by adjusting the pan tilt angle, rotational speed, and water spray volume. This flexibility suits varying mineral fertilizer production demands, whether for rock-based phosphate materials or blended NPK fertilizers. Unlike other granulating approaches, pan granulators operate with lower energy consumption and simpler maintenance procedures. When integrated with a screening machine, the production line can classify granules by size, recycle the undersized materials, and achieve a closed-loop manufacturing process.

What Are the Benefits of Using Pan Granulation for Mineral Fertilizer Processing?

Pan granulation offers multiple technical and economic advantages. The granulating process converts fine mineral powders into manageable pellets, reducing dust emissions and material loss during handling. The resulting fertilizer particles exhibit stable size distribution and improved strength, making them suitable for storage, packaging, and industrial blending. Furthermore, the disc granulator system supports continuous operation and requires less floor space compared with large drum pelletizers.

In addition, pan granulation enhances the value of low-grade ores. Through controlled moisture and chemical adjustment, even marginal mining residues can turn into useful fertilizer materials. This process supports sustainable mine waste management while lowering raw material costs. The integration of granulation machinery with crushing, screening, and drying equipment creates a complete mineral fertilizer manufacturing line that serves both mining enterprises and chemical fertilizer producers.

Conclusion

The transformation of ore-based minerals into high-quality fertilizer particles depends on precise granulation technology. Pan or disc granulators enable mining and processing industries to convert fine mineral materials into durable, uniformly sized granules that meet diverse production requirements. By integrating crushing machines, granulators, and screening systems, enterprises can build efficient mineral fertilizer production lines and achieve sustainable use of mining resources.

A professional fertilizer equipment manufacturer—Yushunxin—provides reliable pan granulation solutions and complete mineral fertilizer production machinery, supporting clients in achieving stable, efficient, and environmentally responsible fertilizer manufacturing. You can visit: https://www.mineralfertilizerproductionsolutions.com/product/disc-granulator-machine/