When businesses consider entering the fertilizer manufacturing sector, the industrial fertilizer production line cost becomes a decisive factor. Investors often underestimate the complexity behind the total budget — it’s not just about buying a few machines, but about integrating equipment, utilities, manpower, and maintenance into a seamless system. A modern production line must balance efficiency, reliability, and scalability to achieve sustainable profits.

Equipment: The Foundation of Production

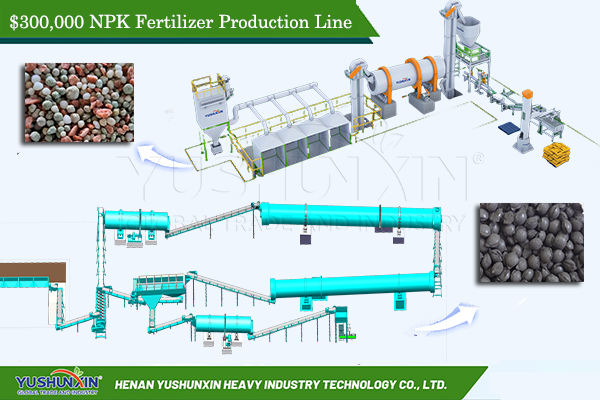

Equipment generally represents the largest portion of the investment. From mixers and granulators to dryers and packaging machines, the selection determines product quality and capacity. For example, an NPK fertilizer plant setup cost varies depending on automation level, production scale, and after-sales support. High-efficiency machines can reduce long-term expenses, but the initial purchase price will be higher. Buyers should compare models, evaluate energy consumption, and consider suppliers who offer full technical guidance to optimize production performance.

Energy Consumption and Operational Expenses

Energy use directly influences profitability. Powering dryers, mixers, and conveyors requires stable electricity or gas supply, and fluctuating energy prices can significantly affect total costs. Many factories invest in energy-saving systems and waste heat recovery to reduce operating expenses. For some investors, an organic fertilizer production line investment can be a strategic alternative because it often consumes less energy and utilizes locally available organic waste, lowering both cost and environmental impact.

Labor and Maintenance Costs

Even with automation, skilled workers are essential to ensure smooth operations. Labor costs include training, safety measures, and regular maintenance of critical equipment. Efficient management helps prevent unplanned downtime and product losses. When evaluating total expenses, companies should plan for spare parts and technical service to keep production lines running continuously.

The Role of Turnkey Solutions

For many entrepreneurs, starting from scratch can be overwhelming. Partnering with a turnkey fertilizer production line supplier simplifies the process, offering design, installation, and staff training in one package. Such suppliers can provide detailed cost forecasts and operational guidance, allowing investors to control budgets more effectively. Get now

Estimating a Practical Budget

Every project is unique, but small to medium-scale facilities can often be established within a $300,000 solution for fertilizer making, depending on capacity and location. It’s essential to consider not only equipment prices but also logistics, utilities, and compliance with local environmental regulations. A transparent cost analysis helps ensure the investment delivers long-term value rather than short-term savings.

Conclusion

Breaking down the cost structure of a fertilizer production plant reveals that success depends on comprehensive planning. By balancing equipment quality, energy efficiency, and labor productivity, investors can achieve a competitive edge in the market. Whether you’re evaluating a chemical or organic setup, understanding these three pillars—equipment, energy, and labor—ensures your production line operates profitably and sustainably for years to come. If you need details, you can visit https://fertilizerequipmentmanufacturer.com/fertilizer-manufacturing-plant-cost/